Rawaan Ibrahim

she/her | age 17 | Edmonton, AB

Edited by Nathan Badry

Classrooms use significant amounts of paper on a daily basis, and even more is thrown out. As the human population continues to grow, more homes are built but at the cost of ecosystems, habitats and agricultural fields. With every house built there are trees cut down, therefore, I wanted to find an alternative to wood paper products as trees are being deforested at an alarming rate. Through experimentation, I was able to utilize mowed grass clippings to make paper out of grass. For the first three trials, I used a similar method to how homemade paper is made; however, grass clippings fell when the paper was moved. I then researched how paper is made commercially and found that chemicals are used. One of those chemicals is washing soda, and through the utilization of this chemical the cellulose fibers at a molecular level broke down to produce a smoother surface, legible to read.

INTRODUCTION

Every second a forest the size of a football field is cut down. Every minute 2,400 trees are cut and every year a forest the size of Switzerland is lost (Toner Buzz [TB], 2022). Deforestation does not only affect forests, but the loss of trees contributes to polluting the environment as pulp and paper are the third-largest industrial polluters of air, water, and land in North America (Watershed Sentinel, 2012). Paper production is the world’s fifth-largest energy consumer (Ellen, 2016). Additionally, the pulp and paper industry exploits more water compared to other industries; however, this statistic does not include the amount of water needed for a tree to mature (TB, 2022). Trees will consume 0.0379 cubic meters of water for every 2.5 centimeters in diameter (Arbor Day Foundation [ADF], 2018).

Depending on the species, trees can take on average 15-30 years to grow (Green Pine Tree Service [GPTS], 2020). Whereas grass takes about three to four weeks to be long enough to mow (Grass Master, n.d.). Additionally, it takes 24 trees to make one thousand kilograms of paper, which is about 200,000 sheets (Oregon State University [OSU], 2021). Manufacturing plants also emit nitrogen dioxide, sulfur dioxide, and carbon dioxide, which are significant contributors to acid rain and the greenhouse effect (Mace, 2015).

Another overlooked dilemma that negatively affects the environment is the accumulation of grass clippings in landfills. During the peak growing season, grass clippings can amount to almost 50% of all waste materials collected (Don’t Trash your Grass, 2014). As grass clippings decompose in landfills, the leachate that is created through the grass clippings contribute to groundwater contamination affecting ecosystems (How to Compost Grass, 2014).

How can we reduce deforestation and utilize already thrown away grass clippings to save the environment? Likewise, can grass clippings be used as an alternative fibre in the production of paper products? This experiment aims to answer if grass clippings can be used as a sustainable and practical alternative without compromising the texture, thickness, and legibility of manufactured letter paper.

MATERIALS & METHODS

I had done a total of eleven trials, adapting the procedure to experiment to what extent can paper be made from grass. At the beginning, I was not aware that a chemical would be needed to break down the cellulose fibres at a molecular level. By using washing soda, the texture of the paper changed dramatically as the paper yielded a smoother surface. In the same way, I thought the mould and deckle would increase the efficiency of the procedure, however, the lightweight qualities of the trial produced tissue paper rather than writing paper.

For the first three trials, I used a similar process to homemade paper by following a YouTube video as my reference (Vijayta, 2020). I used the same steps but boiled the grass fiber until bubbles formed. At first, I was content to stop at this stage as I had made paper out of grass; however, my vice principal suggested going quality over quantity. For the subsequent trials, I adopted chemical techniques used in pulp and paper factories to see if it would help reproduce the texture, thickness, flexibility and legibility of wood paper.

I found that chemicals are used to break down wood fibres at a molecular level. One of the hundreds of chemicals used in paper production is caustic soda (Brennan, 2018). Caustic soda is a common ingredient in laundry detergents and can easily be made at home from baking soda (Gippsland Unwrapped [GU], 2016). Washing soda, which is baking soda baked at high temperatures, is the common name for sodium carbonate (PCC Group Manufacturer of Specialty Chemicals [PCC GMSC], 2021). Sodium carbonate is considered eco-friendly since it occurs in nature in its dissociated form (PCC GMSC, 2021). For this reason, I had chosen washing soda to break down the cellulose fibres in grass clippings as it does not harm living organisms if the paper were to come in contact with them.

For the fourth trial, I used two tablespoons of washing soda, boiled then simmered the mixture for 90 minutes and blended the pulp for one minute. These differences made a significant difference in the end result of the paper as it was smooth and legible like manufactured paper. It was quite difficult for me to contain the pulp within the oil splatter sieve because it did not have a barrier to stop the pulp from floating away in the water. With the help of my teacher, we built a mould and deckle (used to make professional homemade paper) as a possible solution. However, the fifth and sixth papers made from the mould and deckle have a similar texture to tissue paper due to their thinness, transparency and light weight qualities.

The purpose of the seventh and eighth trial was to test run the materials and to time the procedure before the field trip (I had taken a class of fifth grade students to the science lab where they made their own Grassheet’s from scratch). The next day, the students got to color and personalize their own papers and when they finished I compiled their works into a book (the ninth trial). The papers of the students were flat compared to my seventh and eighth trial because they spent a longer time soaking up excess water. Since I was timing myself, I had neglected the importance of soaking as much water as possible, hence the slight bumpiness in trial seven and eight.

The tenth and eleventh trials are from the same batch as I had split it up to test the effects of using hydrogen peroxide as a natural bleaching agent. As a result, the eleventh trial had a slight yellowish hue.

RESULTS

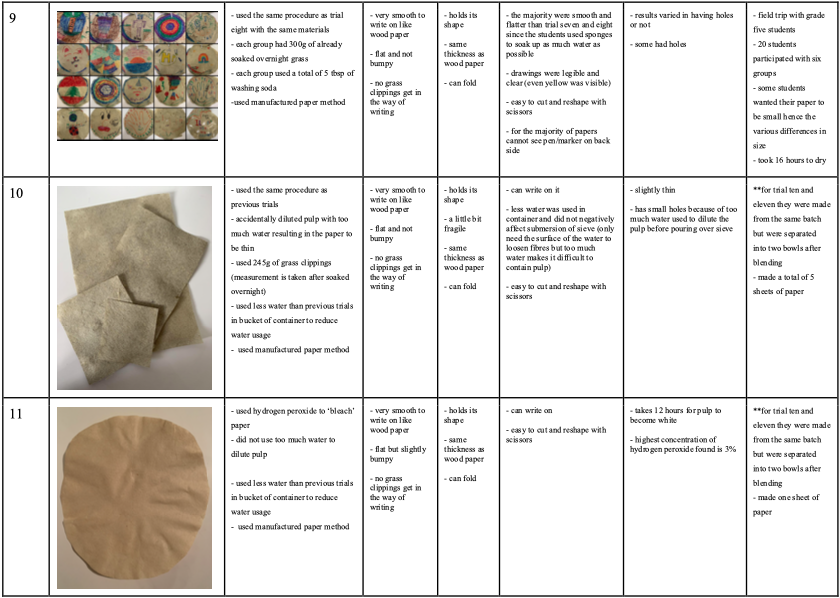

I did a total of eleven trials starting from the beginning of December to the end of April. The procedural differences between each trial as well as the pros and cons are described in more detail in Table 1. The first three trials did not have a similar texture to manufactured paper as grass clippings would get in the way. However, the fourth trial was smooth enough to write on and as thick as a piece of paper. With my teacher's help we built a mould and deckle which was used for the fifth and sixth trial. Due to the inconsistencies in texture, the fifth trial cannot be easily written on because I had poured the diluted pulp mixture on top resulting in inconsistencies since there was no solvent to make the fiber uniform. The sixth trial was submerged completely under water and hence the smoothness and consistency of the paper. Despite this, the sixth trial is as thin as tissue paper and is difficult to write on without creating holes in the process. The seventh, eighth and ninth trial have a slight bumpiness in texture however they still provide a smooth surface that is legible. The tenth and eleventh trial was made from the same batch but were split to test if hydrogen peroxide can bleach the grass fibre. The eleventh trial was soaked for 12 hours in hydrogen peroxide to bleach the paper, resulting in a slight yellowish hue, resulting in a slight yellowish hue. All trials after the fourth are similar if not identical in texture as shown in Figure 1; they are all eligible to write on since they have a smooth surface and the same thickness as manufactured letter paper.

Table 1: Procedural differences, smoothness and flexibility, pros versus cons and notes for each trial

Figure 1: All eleven trials starting with the first on the left side ending with the eleventh trial on the right. Please note that the eighth trial was used in the book.

DISCUSSION & CONCLUSION

Around the world, paper is primarily made from cellulose fibres (1.1-Production/consumption, n.d.). Less than two thirds of paper products come from wood, one third from recycled paper and roughly 5% from non-wood sources (1.1-Production/consumption, n.d.). Therefore, by making paper out of grass it reduces the dependability of wood fibre in the pulp and paper industry. As a result, this experiment proves that grass clippings can be an alternative to wood paper products without compromising the texture, thickness, legibility, and flexibly of wood paper. The fourth, seventh, eighth, ninth and tenth trial show that grass clippings have a similar texture to office paper. On the other hand, the trials made with the mould and deckle resulted in a texture similar to tissue paper.

The potential of grass paper products are endless and can have a significant impact on the environment by reducing one third or more of trash created by the packaging industry (Paper Waste Facts, n.d.). Grassheet is a sustainable, easily accessible, and inexpensive alternative to wood paper products because it tackles two problems in one: reducing deforestation and utilizing grass clippings from landfills. Whether the grass is freshly mowed or is left to dry it does not affect when Grassheet can be produced. Likewise, it will not slow down a company’s production rate since the grass clippings can be utilized any time of the year just like trees (Sustainably Harvesting Trees in the Winter, n.d.). Additionally, companies can utilize the community’s mowed grass clippings as an inexpensive but practical source. By making use of already thrown away grass clippings, companies do not need to spend a fortune in planting and harvesting trees. Not only is Grassheet cheaper because it reuses waste, but it is also simpler in the manufacturing process and does not require multiple processes taking place in several warehouses. As a result, Grassheet will be time and cost effective without compromising the health of the environment.

Grassheet is not limited to being a science fair project but is a proposal for companies to adapt in the future. Furthermore, the field trip reinforces the simplicity of using grass clippings as students can easily replicate it in a school laboratory. On top of that, Grassheet can reduce greenhouse emissions and deforestation, making the world better, cleaner, and healthier.

NEXT STEPS

I would like to make Grassheet a reality by scaling it up to be manufactured by pulp and paper companies. By experimenting with the thickness of the paper, the products of Grassheet are endless, from writing paper to food containers to newspapers. On a larger scale, I would also like to experiment with methods to reduce drying time but maintain a similar energy consumption level to increase production efficiency. I would also like to experiment if the concentration of hydrogen peroxide will whiten the paper completely white as opposed to a slight yellowish hue.

ACKNOWLEDGEMENTS

I would like to acknowledge my teacher, Ms. Lin, for proposing the idea to make flower paper as an expansion of my ninth grade science fair project. Mr. Imran for suggesting grass clippings instead of flowers as they are free and easily accessible. Mr. Thompson for helping me with the construction of the mould and deckle. Ms. Bahja for encouraging me to aim for quality over quantity. Ms. Jorf for encouraging me to participate in the science fair. Ms. Shameeza for guiding me on how to conduct a field trip. Ms. Ameena for facilitating the Grassheet experiment and the students for participating in the field trip.

REFERENCES

Barnhardt Purified Cotton. (n.d.). The Eco-Friendliness of Hydrogen Peroxide. Retrieved April 13, 2022 from https://barnhardtcotton.net/blog/the-eco-friendliness-of-hydrogen-peroxide/amp/

Don’t Trash your Grass. (2014, November 26). Millennium Waste Inc. https://www.millenniumwasteinc.com/news/article/the-best-grass-clippings-waste-management/

Ellen. (2016, November 3). Papercut: Climate Change’s Impact on the Pulp & Paper Industry. Digital Initiative. https://digital.hbs.edu/platform-rctom/submission/papercut-climate-changes-impact-on-the-pulp-paper-industry/

Gippsland Unwrapped. (2016, July 13). How to Make Washing Soda from Baking Soda and Why you Would Want to. https://gippslandunwrapped.com/2016/07/13/how-to-make-washing-soda/

Grass Master. (n.d.). How Long Does it Take for New Grass to Develop? Retrieved November 26, 2021, from https://www.thegrassmaster.com/how-long-does-it-take-for-new-grass-to-develop/

Green Pine Tree Servies. (2020, November 19). How Long Does it Take for a Tree to Grow. https://greenpinetreeservice.com/how-long-does-it-take-for-a-tree-to-grow/

Helmenstine, A.M. (2020, February 3). What is Caustic Soda? ThoughtCo. https://www.thoughtco.com/what-is-caustic-soda-608493

Mace, R. (2015, September 25). Impact of Paper Production on Environment. Efile Cabinet. https://www.efilecabinet.com/impact-of-paper-production-environment-paperless-office/

Oregon State University. (2021, April 26). How do people make paper out of trees and why not use something else?. https://theconversation.com/amp/how-do-people-make-paper-out-of-trees-and-why-not-use-something-else-156625

Paper Waste Facts. (n.d.). The World Counts. Retrieved October 16, 2022, from https://www.theworldcounts.com/stories/paper-waste-facts.

Sustainably Harvesting Trees in the Winter. (n.d.). West Fraser. Retrieved October 16, 2022, from https://www.westfraser.com/responsibility/stories-responsibility/sustainably-harvesting-trees-winter.

Toner Buzz. (2022, March 8). Deforestation Facts and Statistics. https://www.tonerbuzz.com/blog/deforestation-facts-and-statistics/

Vijayta Sharma. (2020, August 1). DIY Homemade paper/ How to make homemade paper without frame/ recycle paper. [Video]. YouTube. https://m.youtube.com/watch?v=sHbk9UAAXGE

Watershed Sentinel. (2012, October 15). The Pulp Pollution Primer. https://watershedsentinel.ca/articles/the-pulp-pollution-primer/

1.1 - Production/consumption. (n.d.). Environmental impact assessment and environmental auditing in the pulp and paper industry. Retrieved October 16, 2022, from https://www.fao.org/3/V9933E/V9933E01.htm#ch1.1.

ABOUT THE AUTHOR

Rawaan Ibrahim

Rawaan Mohamed Said Mohamed Ibrahim, and yes that is her full, real name :), is a Egyptian born Canadian Muslim. Her favorite food is chocolate, and she believes in eating dessert every single day. Hence her passion for baking healthy, homemade desserts. She enjoys DIYing her school supplies and building new things that can help those around her. Thus the reason for her innovative initiative of making paper out of grass aka Grassheet.