NADINE PERSAD

she/her | age 16 | Creston, BC

Best in Fair Gold Medalist West Kootenay Regional Science Fair (WKRSF) 2022 | Biotechnology Category Award WKRSF 2022 | BC Agriculture in the Classroom Award 2022 | BC Game Developers Innovation Award 2022 | CWSF Excellence Bronze Award 2022 | Challenge Award in Agriculture, Fisheries | and Food CWSF 2022

Edited by Katie Manas

INTRODUCTION

It is estimated that up to 32% of food is lost or wasted each year (Lipinski, 2013). This statistic likely underestimates spoilage in Canada with our vast distances and remote populations. Farmers work hard to feed Canadians, but the struggles of shipping fresh food to remote and rural communities impact many citizens. Some common reasons for food spoilage are light, physical damage, microorganisms and enzymes. The world needs reliable post harvest treatments to decrease the wastage of food. There are existing technologies to preserve produce, including edible coatings, gassing, and irradiation. There are environmental and health concerns with many of the current post harvest treatments (Anand and Sati, 2013) For example, chlorine is widely used to decrease microorganisms and delay spoilage, but there is evidence that it can encourage the formation of trihalomethanes which are known to be carcinogenic (Ali et al., 2017). In Canada post harvest treatments are not considered food additives, so consumers have no way of knowing what treatments have been applied to their produce.

A promising ingredient found in insect exoskeletons and crustacean shells is chitin. This is a polysaccharide that many scientists are interested in as it is a plentiful resource with promising properties. Most emerging research has focused on a breakdown product of chitin known as chitosan (Antonio et al., 2017). Chitosan is commercially attractive as it contains a positive charge. This allows it to bind to a diverse range of molecules. Preliminary studies conclude that chitosan has antibacterial and antifungal properties (Al-Tayyar, 2020). Chitosan’s positive charge allows it to bind with the negatively charged bacterial cell wall, disrupting the function of pathogenic bacteria (Jarolimkova, 2015). There has been early research into edible coating using crustacean chitosan, but there is a paucity of research on insect chitosan. Unlike crustaceans, insects are rarely allergenic and can be economically farmed year-round in an environmentally safe manner.

This project aimed to develop a protocol to isolate chitosan from cricket powder and create a sprayable solution of this chitin derivative. The ability of chitosan spray to delay the spoilage of fresh fruit would then be tested. I have developed a post harvest treatment from cricket powder that is biodegradable, food-safe, and environmentally friendly to help prolong the shelf life of fresh produce.

materials & methods

There are several steps to isolate chitosan from cricket powder (Jarolimkova, 2015). To deproteinize the cricket powder, 200 g of 100% cricket powder was mixed with 2 L of 1 M sodium hydroxide (NaOH), heated to 95 °C and stirred for 6 hours. This solution was sieved through a 200 µm sieve and rinsed with tap water until pH paper read neutral. The sample was then dried at 65 °C for 8 hours. The sample was then demineralized by mixing the deproteinized sample in 20 g oxalic acid mixed in 2 L water. This was stirred at room temperature for 3 hours, sieved through a 100 µm sieve, washed until neutral with tap water, and dried at 65 °C for 8 hours. The chitin sample was deacetylated to chitosan by mixing in 16.75M NaOH solution times 3 hours at 90 °C. The sample was sieved through a 200 µum sieve and dried at 65 °C for 8 hours. A 1% aqueous acetic acid solution was created as the control. Chitosan was dissolved in half of the 1% acetic acid solution to make a 1% chitosan solution. Organic fruit was purchased, and two halves of the same fruit were used for cut samples. The fruit was sprayed and kept in a dark room at 20 °C and photo documented daily until it moulded. The experiment was continued and photo documented for 23 days.

RESULTS

After deproteinization, only 5% of the initial sample mass was recovered (10.89 g of the 200 g). Demineralization resulted in a yield of 93% (10.09 g of the 200 g) while deacetylation resulted in a 79% yield (8.00g of 10.09g). The final chitosan yield was 4%.

The control versus the chitosan spray showed the more significantdifference in browning for the cut fruit.

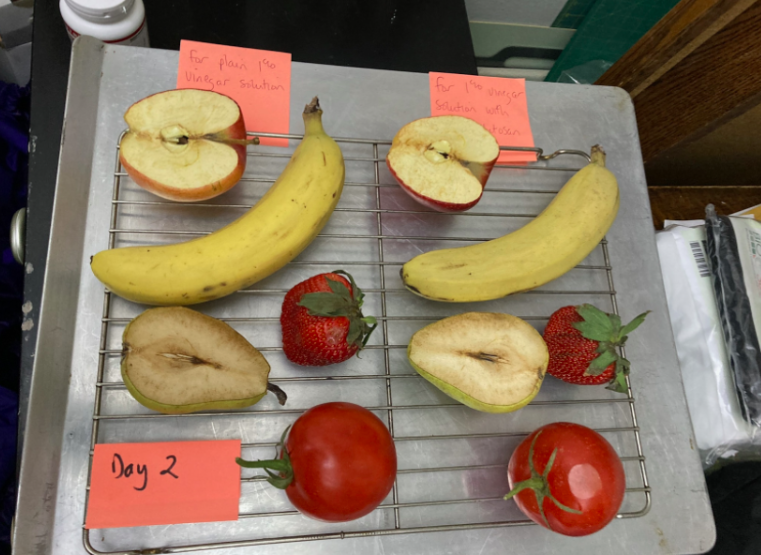

Figure 1: Days 2 (top) and 23 (bottom) of Control and Chitosan-Sprayed Fruit.

The control pear moulded on day five and the chitosan pear moulded on day six.

The control strawberry showed visible moulding at day four, with the chitosan strawberry moulding at day sixteen. The chitosan tomato moulded on day nine at the site of a bruise. The bruise was not seen until several days into the experiment. The control tomato did not mould by day twenty-three. Particles in the chitosan spray were visible on the tomato but not on the other fruit. The cut apple pieces looked similar until day sixteen, when there was mould on the control apple. The chitosan apple never moulded. Both bananas showed browning by day ten, but the control banana was much browner by day seventeen. Mould appeared on both bananas on day twenty-two.

Figure 2: Comparison of Days until Moulding for Fresh Fruit Treated with a Control 1% Acetic Acid Spray Versus a 1% Chitosan Spray.

DISCUSSION

Efficiently, safely, and economically feeding the world is an important current issue. Post harvest treatments are one way to ensure that food produced remains fresh on its journey to consumers. Chitosan has attracted attention as it is safe to consume, biodegradable, and has demonstrated antibacterial and anti-fungal properties. Most of the existing research has been done on shrimp and crab exoskeletons as they are waste products. With the limited and seasonal nature of the seafood industry, it is interesting to look to insects as an alternative chitin source. With current interest in insect farming for food, work has been done to efficiently mass-produce insects in an environmentally sensitive manner. There is no agreed-upon procedure to isolate insect chitosan as most protocols have been developed for crustaceans. There is some evidence that altering the processing times and choice of reactants can affect the yield of chitosan (Abidin, 2020). This project modified existing protocols developed primarily for chitin extraction from shrimp, and has shown that after deproteinization, demineralization, and deacetylation, a yield of 4% chitosan can be achieved from cricket powder. This percentage was similar to crustaceans (Ibitoye et al., 2018).

Dissolving chitosan in a food-safe medium proved challenging. Research suggests that chitosan requires a mildly acidic solution to dissolve, so a 1% solution of acetic acid was created (Ahonkhai, 2007). When the spray dried on the fruit, larger particles could still be seen on the tomatoes. This was disappointing as it was hoped the chitosan would fully dissolve, although grinding the chitosan to a finer powder might be a solution. Balancing the strength of the vinegar and dissolving the chitosan had to be managed, as an adverse taste had to be avoided. It was encouraging that most the chitosan-sprayed fruit rotted slower, except the tomato. Physical trauma that became visible during the experiment is thought to explain this anomaly. Conclusions from this study are difficult as the sample size was small, and due to the season, untreated fruit directly from a farm was not available.

CONCLUSION

In this experiment, chitosan was isolated from crickets with a fairly simple procedure, giving similar yields as from crustaceans. The chitosan spray did seem to slow visible rotting on most of the tested fruit, which is encouraging, although it deserves further testing with larger sample sizes for confirmation.

It would be interesting to try varying the strengths, temperature, and times for the deproteinization, demineralization, and deacetylation to see if it is possible to increase the yield of chitosan from cricket powder. Also, it would be interesting in the future to confirm with a mass spectrometer or electron microscope how much of the final sample is pure chitosan. Finally, it is also an area of future study to change the percentage of chitosan in the post harvest spray.

REFERENCES

Abidin, N. A. Z., Kormin, F., Zainol Abidin, N. A., Mohamed Anuar, N. A., & Abu Bakar, M. F. (2020). The potential of insects as alternative sources of chitin: An overview on the chemical method of extraction from various sources. International Journal of Molecular Sciences, 21(14), 4978. https://doi.org/10.3390/ijms21144978

Ahonkhai, E. I., Arhewoh, I. M., & Okhamafe, A. O. (2007). Effect of solvent type and drying method on protein retention in chitosan-alginate microcapsules. Tropical Journal of Pharmaceutical Research, 5(2), 583–588. https://doi.org/10.4314/tjpr.v5i2.14635

Ali, A., Yeoh, W. K., Forney, C., & Siddiqui, M. W. (2017). Advances in postharvest technologies to extend the storage life of minimally processed fruits and vegetables. Critical Reviews in Food Science and Nutrition, 58(15), 2632–2649. https://doi.org/10.1080/10408398.2017.1339180

Al-Tayyar, N. A., Youssef, A. M., & Al-hindi, R. (2020). Antimicrobial food packaging based on sustainable bio-based materials for Reducing Foodborne Pathogens: A Review. Food Chemistry, 310, 125915. https://doi.org/10.1016/j.foodchem.2019.125915

Anand, S.P. & Sati, N. (2013) Artificial Preservatives and Their Harmful Effects: Looking Toward Nature For Safer Alternatives. International Journal of Pharmaceutical Sciences and Research, 13(9), . 2496–-2501.

de Queiroz Antonino, R., Lia Fook, B., de Oliveira Lima, V., de Farias Rached, R., Lima, E., da Silva Lima, R., Peniche Covas, C., & Lia Fook, M. (2017). Preparation and characterization of chitosan obtained from shells of shrimp (Litopenaeus Vannamei Boone). Marine Drugs, 15(5), 141. https://doi.org/10.3390/md15050141

Yilmaz Atay, H. (2019). Antibacterial activity of chitosan-based systems. Functional Chitosan, 457–489. https://doi.org/10.1007/978-981-15-0263-7_15

Benhabiles, M. S., Salah, R., Lounici, H., Drouiche, N., Goosen, M. F. A., & Mameri, N. (2012). Antibacterial activity of chitin, chitosan and its oligomers prepared from shrimp shell waste. Food Hydrocolloids, 29(1), 48–56. https://doi.org/10.1016/j.foodhyd.2012.02.013

Ibitoye, E. B., Lokman, I. H., Hezmee, M. N., Goh, Y. M., Zuki, A. B., & Jimoh, A. A. (2018). Extraction and physicochemical characterization of chitin and chitosan isolated from house cricket. Biomedical Materials, 13(2), 025009. https://doi.org/10.1088/1748-605x/aa9dde

Jarolimkova,V. (2015). Preparation and Characterization of Antimicrobial Packaging Films from Cricket Chitosan Enriched with Schisandra Chinensis Extract. Masters Thesis, Packaging Logistics, Lund University. Retrieved from https://lup.lub.lu.se/luur/download?func=downloadFile&recordOId=7360085&fileOId=7360145

Lipinski B, Hanson C, Lomax J, Kitinoja L, Waite R, & Searchinger T. (2013). Reducing Food Loss and Waste. Working Paper, Instalment 2 of Creating a Sustainable Food Future. Washington, DC, USA. Retrieved from: https://files.wri.org/d8/s3fs-public/reducing_food_loss_and_waste.pdf

Yan, D., Li, Y., Liu, Y., Li, N., Zhang, X., & Yan, C. (2021). Antimicrobial properties of chitosan and chitosan derivatives in the treatment of enteric infections. Molecules, 26(23), 7136. https://doi.org/10.3390/molecules26237136

ABOUT THE AUTHOR

Nadine Persad

is currently in Grade 11 at Kootenay River Secondary School. She has been participating in science fairs since she was in kindergarten, and this is her second time participating in CWSF. A subject that has captured her interest was crickets. Many people do not realize the properties of these small but mighty creatures. Aside from Science Fair she also enjoys soccer, skiing and volleyball and works as a lifeguard and swim instructor. Nadine hopes to continue her passion for science in university.