Hannah Boucher

Age 19 | St. John, New Brunswick

NB Regional Science Fair Senior Gold Medalist

This paper investigated the influence of specific variables, including force, pressure, bending angle, volume, and displacement on the movement of pneumatic pouch motors. After conducting a review of the literature within the field of soft robotics, a gap was found in the use of pneumatic pouch motors due to the lack of current research available in this field. In addition, most research previously conducted has been focused on more complex actuators, with little focus on simpler and more cost-efficient forms. Therefore, this research aimed to experimentally determine a mathematical model to represent the motion of pneumatic pouch motors.

INTRODUCTION

Problem Statement

There is a problem with the cost of current pneumatic artificial muscles, which has the potential to result in a negative impact on the health of those suffering from impaired motor functions. Despite current research being dedicated towards the modelling of these actuators to make them more accurate and lower discrepancies between the models and prototype devices, cost will continue to be an issue, especially when considering the intended use of the pneumatic actuators. If intended for medical purposes such as rehabilitation or an additional form of patient care, cost can act as a barrier to provide the patients with this form of treatment. Lower cost alternatives also need to be examined to consider the economic side the actuators that has a direct impact on availability to patients.

Current Soft Robotic Technology

Soft robotics is a specific field within the realm of robotics that uses highly compliant materials to imitate the movements of living organisms. The flexibility of soft robots makes them ideal to use with the human body, as the technology intended to replicate average movements is able to do so without being too rigid or having a limited range of motion experienced with other robotics. According to Biggar & Yao, because of extended life expectancy and sedentary lifestyles, long term health of the population is of concern (2016). Both Biggar & Yao and Maeder-York et al. argue that these concerns are illustrated by the increase in disabilities caused by medical conditions such as stroke, with 76% of stroke victims in theUnited States left with disabilities (2016; 2014). With the need for rehabilitation for these disabilities, soft robotics offer a solution to regain the loss of function.

One of the challenges encountered is the time between the conceptual design of the robotic device and the construction of a functional prototype, however pouch motors provide a solution to this problem (Niiyamaetal. 2014).The pouch motors enhance the mass production of robots using accessible materials, which shorten the wait period between idea and reality, and allow for easy fabrication and prototyping of robotic systems (Niiyama et al. 2014; Niiyama et al. 2015). The pouch motors are pneumatic devices made from sheet materials by heat bonding, consisting of gas-tight bladders (Niiyamaetal.2014). They are able to use the mechanical work of the fluid into the deformation of the pouches to exert forces via output tabs on the edges of the pouch, necessary for the actu- ators to function (Niiyama et al. 2015). Additionally, these pouch motors can be layered to create more complex pneumatic systems that work together from a connected control system to create oper- able robots, such as rehabilitative robots.

Use in Rehabilitative Devices

One of the most promising uses of pneumatic pouch motors is their use in medical robots for physical rehabilitation. Becauseoftheir flexible nature and compliant materials, soft robotics provide a valuable resource within the medical field, especially for physiotherapy. While evaluating devices made for the rehabilitation of hand, wrist, and thumb functions, researchers have come to common conclusions about their devices surrounding their future development to be more accessible for patients and to more accurately fit targeted motion paths (Biggar & Yao 2016; Maeder-Yorketal. 2014; Chu & Patterson 2018; Ates et al. 2017).

Another common point across the research is the use of pneumatic actuators for rehabilitation devices. The EXOWRIST prototype uses pneumatic actuators to achieve 2 degree-of-freedom movements, which Andrikopoulos and his peers’ claim have similar properties of organic muscle, which is validated by the research of Al-Fahaam et al., who argue that the pneumatic actuators perform similarly to organic muscles (Andrikopoulos et al 2015; 2018). The benefits of pneumatic actuators over other forms of soft robotics arise from their ability to follow linear contractions, whereas soft actuators require complex mathematical modelling for their nonlinear behavior (Al-Fahaam et al. 2018). Additionally, Chu & Patterson (2018) notice the recent emergence of pneumatic rehabilitation systems throughout their synthesis of 44 devices, and view this trend as a result of the pneumatic systems allowance for more specific hand motions than other systems. Along with their similar properties to organic muscle, the pneumatic systems do not add an excessive amount of weight to the device, falling within the range of acceptable weight (Chu & Patterson 2018). The pneumatic actuators are able to provide safer interaction between patients and the device, as they are still made of soft materials, however because of their linear contractions, they must be secured rigidly to the patient or be combined with a rigid serial link mechanism to keep them in place, which does not allow for the device to be adjusted easily (Al-Fahaam et al. 2018). The need for the device to be adjustable, have minimal weight, and not interfere with hand functions is to provide accessibility and portability for the patients so they are able to use it as a home-based device, providing the additional rehabilitation outside of viewing a phys- iotherapist.

Need for Mathematical Modeling & Current models

Through the development of mathematical models, the pouch motors can be refined for a more exact fit for their desired functions. As suggested by many researchers currently working on the development of rehabilitation prototypes, improving the mathe- matical models to decrease percentage error and considering the effects of other variables on the actuators will improve the overall function of the devices (Al-Fahaam et al. 2018; Greer et al. 2017; Niiyama et al. 2015). The mathematical modeling of the pneu- matic pouch motors will allow for more accurate plans for the use of this technology within robotics and for more accurate devices within the realm of physical rehabilitation.

Current models being researched and data being collected consider the effects of pressure and force in relation with one another, the effects of tension, torque, and range of motion on the pouch motors’ behaviors, static force-length and moment-angle relationship, relationship between angles and pressure control, and the manipulation of pressure while considering the angular motion that controls the device (Al-Fahaam et al. 2018; Niiyama et al. 2015; Niiyama et al. 2014; Sun et al. 2015; Andrikopoulos et al. 2015). Taking into the accounts of other researchers and compiling them together illustrates the importance of the modeling systems and the accuracy that they can provide.

Cost-Saving Potential

Because of their use in rehabilitative devices, there is a need to keep the actuators cost effective for the patients. Recovery is in- tensive and with the increasing number of patients, it puts additional strain on physiotherapists and healthcare budgets (Biggar & Yao 2016). By developing rehabilitative devices, it aims to reduce this physical strain put on physiotherapists while allowing them to take on more patients as the device handles most of the manual labor (Biggar & Yao 2016). The ability to be used by the majority of the patients however is dependent on the cost effectiveness of the device. Researchers currently developing low-cost rehabilita- tive devices have taken different approaches to maintaining the low-cost, including 3D printed exoskeletons (Rocha et al. 2018). Additionally, for the devices to provide the most promising form of rehabilitation, they also need to be portable and adaptable for

patient use so they are able to use the devices at home without the need of medical professionals to facilitate the devices. The use of pneumatic pouch motors in these rehabilitative devices meet the necessary low-cost materials while providing adaptability and portability to the devices because of their soft robotic technology that allows them to be more flexible and less rigid than traditional robotics while still providing the necessary support.

Discrepancy & Hypothesis

After reviewing the literature surrounding the use of soft robotics, there is a need for research to be conducted on the uses of pneumatic pouch motors as well as requests to further investigate different variables that are known to impact other forms of pneumatic actuators. While there is some experimental evidence in the form of mathematical models that currently represent specific forms of actuators, these researchers still provide recommenda- tions for future research to continue the experimentation and col- lection of quantitative data to optimize current findings (Al-Fahaam et al. 2018; Biggar & Yao 2016; Greer et al. 2017; Niiyama et al. 2015). In addition, little to no experimental data has been collected as of yet regarding the use of pouch motors and their specific uses as pneumatic actuators, therefore warranting the research necessary to determine these relationships. By collecting quantitative data for pressure, force, bending angle, and volume variables respectively, they can be used to represent the pouch motors while also considering the work done on different forms of actuators to compare similarities and differences.

Considering the previous work done in this field it is hypothesized that pressure will have an effect on the force exerted, the bending angles, displacement, and the volume of the pouches. Furthermore, considering the models previously determined for different forms of actuators, the relationship between pressure and force and pressure and bending angle is likely to be a non-lin- ear relationship.

METHODS

Introduction

The impact of input pressure on the dependent variables of muscle type pneumatic pouch motors was experimentally determined. The input pressure of the device was gradually increased and then decreased over time while simultaneously collecting data about the force exerted, bending angles, displacement, and volume of the pouch motors. After experimentation, the collected data was analyzed to determine the mathematical relationship between the input pressure and the force exerted by the pouch motors.

Due to the physical and mathematical nature of the experiment, a scientific experimental approach provides the best method to describe the relationship between the variables by collecting quantitative data to determine the mathematical relationships be- tween the input pressure and output force of the pneumatic muscles.

This method of inquiry aligns with previous research done in the field. Al-Fahaam and his peers used a similar approach to evaluate models for the extending McKibben artificial muscles that have been reinforced to prevent extension. These researchers investigated the effect of displacement, pressure, and force, as well as the geometrical parameters of the device, on the performance of the actuators (Al-Fahaam et al. 2018). Additionally, they explain that the diameter, or width, of the pouch motors do not have an effect on the maximum extending of the pouches, which is only dependent on their length. Their analysis of the quantitative data that was collected contributes most greatly to this experiment being conducted because of their work determining mathematical models to represent the extensor bending muscles, along with the importance they place upon future work in this field, justifying the purpose behind this research (Al-Fahaam et al. 2018).

In addition, Ryuma Niiyama and his associates have worked on the use of pouch motors and computational design and created a computer-generated hand that is able to gesture and hold a foam ball (Niiyama et al. 2015). They chose to use a heat bonding method, as well as the use output tabs attached at the edges of the pouch motors to deliver the mechanical power exerted by the pouches as they contract and expand, aligning with the procedures followed from the Open Soft Machines Website (Niiyama et al. 2015). Combined with the established need for controllable robotic systems to help neurologically impaired or recovering patients by Maeder-York et al. and Biggar & Yao, the quantitative analysis of pouch motors provides a plausible solution (2014; 2016). By comparing the methods that will be used throughout this paper with those of which in the previously mentioned studies, this method aligns with the field of research and will use similar experimentation to add to the research currently available.

Variables

The independent variable of this study was the input pressure of the device, and the dependent variables were the output force exerted, the bending angle, volume, and displacement of the pouch motor. The bending angle of the pouch motors refer to the angle of the entire pouch as curls while being inflated, while the volume refers to the volume inside the individual compartments of the pouch motors as they are being inflated. The independent variable was varied over time to determine its effect on the independent variables. These relationships were then determined by plotting various scatter plots relating the variable together to determine the relationship between them. This experimental method incorporated the use of data collection instruments and technologies in order to collect the required data including: inflation control system, sensors, and slow-motion video analysis, which all allowed to a more accurate reading of the variables. The variables investigated in this paper align with the research question of the investigation as they will be analyzed to determine the mathematical relationship of the linear and curling pneumatic pouch motors.

Data Collection Instruments

Collection instruments were required in order to conduct the exper- iment and obtain the quantitative results needed. The instruments used for this inquiry were a Vernier dual-range force sensor with compatible LoggerPro software, slow-motion video camera, and the Arduino based Programmable Air control system.

The Vernier sensors connect to the computer through an interface and are recognized by the LoggerPro software. The specific sensor used for this investigation was the dual-range force sensor, which is able to measure pushing and pulling forces exerted against it. The sensor was used to measure the pulling force exerted by the pouch motors as they contract and extend as air is let into and out of the pouches, with respect to the time interval to be compared with the additional variables.

The slow-motion camera was used in order to collect displacement data as the pouch contracts and extends. Because the displacement values are so small with respect with the pouches that are contracting, the slow-motion camera allows for the displace- ments to be accurately reported at the specific pressure input.

The Arduino based Programmable Air system consists of a control board with Aiyima brand medical booster pumps (air pumps), which are able to release high pressure air while also generating a vacuum. The control board is connected to an additional valve board by attaching to connectors on the sides. The valve board consists of three valves which can be individually controlled, providing a controlled path for air from the board to the desired location (Shrivastava 2019). The purpose behind the construction of the programmable air system was to produce a cost-effective and “maker friendly” option for programmable air sources that are required to experiment with inflatables (Shrivastava 2019). Shrivastava’s intentions of producing a cost-effective and easy-to-use device align with the purpose behind this inquiry allow for a more affordable form of soft robotics to be used for patient car in the form of rehabilitation of prosthetics. This system allows for the pressure differential between atmospheric pressure and the pressure inside the pouch to be monitored while the air-supplying and air-discharging processes are occurring simultaneously. This collection mechanism can control the data collection process, as all other variables are dependent on the input pressure and allows for connections between the variables to be made after the analysis of the data.

The experimental setup of the Programmable Air and con- nection to the Arduino software and connection to the pneumatic pouch motor can be seen in Appendix A.

Templates

For this experiment, two different templates of pouch motors were investigated in order to compare their experimental results against one another. The linear and curling pouch motor templates were chosen because of the similar nature of their composition, which allowed for more simplistic comparisons between the two. These templates, that are shown in Appendices B & C, were retrieved from the Open Soft Machines website where there are many oth- er templates and forms of soft robotics available to focus on the implementation of soft robotics for further investigation to be developed for future technologies. The website, directed by Ryuma Niiyama, provides an essential resource for this research as it provides information on the forms of soft robotics, aligning with other literature within the field.

Procedure

The pouch motors were constructed by using a template to trace the desired pattern for the pouch motors onto the sheet of 0.006mm polyethylene plastic. The dial on the heat sealer was set to the heat setting between 5 and 6, which was the required setting to ade- quately seal the films. The pouch motors were then sealed along the indicated lines on the outside of the pattern first, as the arm was pushed down and held for 3-5 seconds to seal the plastic films together. The sealing process was repeated until all of the outer seals of the pattern were complete. The partition seals inside the pattern were then made by inserting a narrow piece of cardboard between the partition lines against the heating section of the heat sealer so it is not able to apply the heat to the plastic to bond the sheets together in this section. This step made the tunnels between the subdivided compartments for the air to flow through. The pouch motor was then carefully cut out along it’s outlines, ensuring not to cut along the seals. The position of the air inlet hole was chosen to be near the center of the pouch within one tunnel and was made by using the needle to carefully puncture a hole for the needle to go through, without puncturing the other side. This process was repeated four more times for the same pattern, and then five more times for each of the two other patterns to produce five pouches of the same pat- tern for three different patterns.

The programmable air control system was used to supply and discharge air out of the pouch motors while simultaneously monitoring the pressure difference between the atmosphere and within the pouch. The needle end was connected to the tubing. Before the process began, the Pressure Sensor example of the Programmable Air system was run to determine the atmospheric pressure, which was then recorded. The needle was placed through a piece of strong double-sided adhesive tape and then in the air inlet hole while using the tape to connect the needle to the pouch. A piece of masking tape was then placed over the needle to help eliminate any air lost through the small hole. A piece of string was cut and then tied through the output tab at one end of the pouch motor and then attached to the Vernier dual-range force sensor clamped to the counter surface. The sensor was zeroed while the pouch was pulled until just before the sensor detected a force and then was fixed to the counter.

The data collection process then began by uploading the OpenSoftMachineTest example coding to the board to run the system to inflate and deflate the pouches while monitoring the pressure differences within the pouches. The initial atmospheric pressure was upload to the code. The collection process was let run for two minutes and then repeated for three trials.

The same procedure as above was used to control the input pressure of the pouch motor using the Programmable Air control system, while simultaneously monitoring the changes in the bend- ing angle of the pouch. This value was quantified by using a piece of paper rolled into a cylinder, which was adjusted to the specific curvatures at the specific input pressures. The equation θ=2πl/C was used to determine the bending angle of the pouches by mea- suring the circumference of the circles that fit the curvatures, and using the length of curvature of the pouches to solve for the angle θ. The results were recorded to be later analyzed.

Displacement data was also collected using the Programmable Air system to control the independent variable of the experiment. The input pressures of the device were left to increase and decrease while examining their effect on the total displacement of the pouch motors. This data was collected by using a slow-motion video camera. A ruler was placed in the video frame with the zero mark at the fixed end of the pouch motor. The video was recorded as the air supplying and air discharging mechanisms occurred and looked at the difference from the initial position when the pouch was deflated and to the desired point of inflation of the pouch.

Volume data was determined by measuring the diameters of the individual compartments of the pouch motors, as well as the individual lengths of curvature. These values were recorded, and then left to be further analyzed in order to determine the volume as the pouches inflate.

The entire collection process was repeated for the other template (curling) of pouch motor, to compare thedifferencesbetween the dependent variables between the two templates.

Results

The data collected for the aforementioned variables is presented below in a series of graphs, tables, and mathematical analyses. These results were necessary to relate the variables to one another and determine the mathematical model of the linear and curling pouch motors.

The following table references the variables that will be used in the results section of this paper. These identified variables will appear on both graphical representations and the mathematical analyses of the results. The variables used throughout the results section are defined in Appendix D.

Pressure difference and force vs. time data for Linear, Angular, and Curling Pouches 1, Trial 1 can be found below. These figures illustrate the relationship between the force and pressure variables. The raw pressure data was collected in arbitrary units, but then converted to kPa using the conversion PkPa=P×0.1994+101.3. The force and pressure sensors did not collect on the same time interval, therefore the results had to be plotted independently of one another.

Figure 1: Scatter plot of linear pouch 3, trial 1 pressure dif- ference between atmospheric pressure and the pressure inside the pouch motor compared to force versus time.

As can be seen on the corresponding figures, when there was a maximum input pressure of the pouches there was also a maximum force exerted, as well as when there was a minimum pressure there was a minimum force exerted.

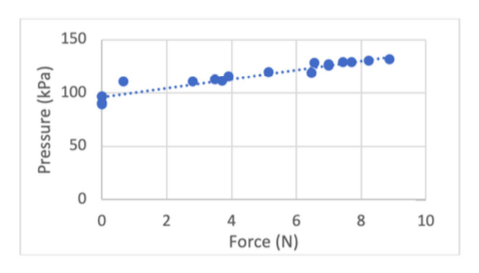

The corresponding points from Figure 1 were then plotted against one another on a pressure vs. force graph. Figure 2 represent this pressure vs. force graph, which illustrate a linear relationship between the two variables, providing the equation for the linear trendline and the R2 values.

Figure 2: Scatter plot of linear pouch 3, trial 1 pressure com- pared to force exerted. y = 4.2316x + 96.21 R2 = 0.9235

Pressure was then compared to the bending angles of the pouch motors; however, these angles could not be measured directly because of the nature of the pouches. The bending angles of the pouches were determined by using the equation θ=2πl/C, where C is the cir- cumference of the pouch if it were to continue and create an entire circle and l represents the length of curvature (Appendix E). Figure 3 represents the relationship between the input pressure of the device and the bending angle of the pouches.

Figure 3: Scatter plot of linear pouch 3, pressure difference compared to bending angle. y = 5.7538x + 107.34 R2 = 0.9723

Next, force and displacement data were compared by plotting them against one another for both templates of pouches. It can be seen that the relationship between the two variables is no longer linear (Figures 4 & 5).

Differential equations were used to determine a relationship that best represents the functions produced by these graphs. Differential equations were chosen to represent these functions as they allow for a more accurate fit than the trend lines produced from the spreadsheets and are commonly used to model rates of change. The calculations shown in Appendices F & G show the steps used to determine the differential equations that best fit the functions produced by the observed data points for both the linear and curling pouch motors, as well as the functions plotted on graphs with the data points.

Figure 4: Scatter plot of force vs. displacement data (red) with calculated differential equation (green), for linear pouch.

Figure 5: Scatter plot of force vs. displacement data (green) with calculated differential equation (red), for curling pouch.

As can be seen from these graphs, the determined trendlines fit the data more accurately, and are able to provide a relationship between the variables. The next graphs produced compared the pressure of the pouches with their volume as they inflated. These graphs, Figure’s 6 & 7, illustrate another linear relationship between the two variables.

The interior volume of the pouch motors was determined by examining the individual compartments of the pouch motors. To determine these values the cross-sectional areas were determined and then multiplied by the lengths of the compartments, which is equal to the width of the pouches, and then multiplied by the number of compartments in the pouch. The equation A=1/2 r^2 (α-sinα) was used to determine the area of a circular segments, which is one half of the cross-sectional area. This value was then multiplied by two and the length of the compartments to determine the volume of one of the individual compartments, as can be seen below in Figure 6, was then multiplied by the number of compartments to determine the total area.

Figure 6: Scatter plot of linear pouch 3, pressure compared to volume. y = 2.1986x + 104.81 R2 = 0.9597

Figure 7: Scatter plot of curling pouch 2, pressure compared to volume. y = 2.2464x + 104.15 R2 = 0.9881

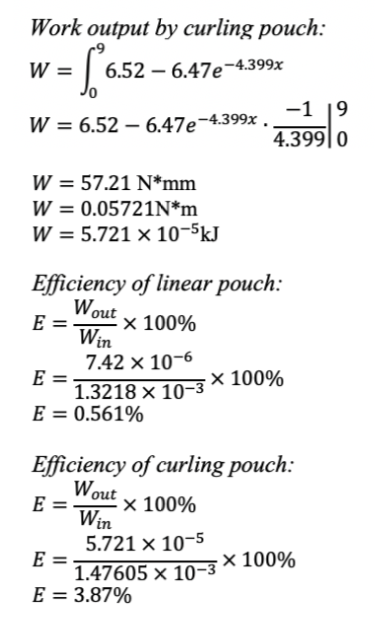

By producing force vs. displacement and pressure vs. volume graphs, the area under each of these curves represents the work done by the pouches and can be determined by taking the integral of the functions. The input work would be represented by the pressure-volume graphs, while output work is represented by force-displacement graphs. Using the work input and output of the pouch motors, the efficiency can be determined. The calculations performed in Appendix H show the work done by both the linear and curling pouches and their efficiency.

These results that were collected and analysed allowed for the determination of mathematical models for the linear and curling pneumatic pouch motors and for conclusions to be drawn from the efficiency calculations.

CONCLUSION

Discussion

As can be seen from the previously shown figures, there evidently is a relationship between the input pressure of the device and the force exerted, displacement, bending angle, and volume of the pouches. From the analysis of these results, it appears that the two templates used experience similar relationships between the variables. Considering the work of Hassanin Al-Fahaam and his associates, this is not necessarily unexpected as the width of the pouch motors does not have an effect on the forces they are able to exert, but length does (Al-Fahaam et al. 2018). While the widths of the templates differed, their lengths were relatively the same.

Despite the pouch motors low efficiency, they are still able to produce their desired motions. As shown above, the efficiency of the curling pouch is greater than that of the linear one. This may have occurred due to the difference in the number of individual compartments of the two templates. The curling pouch consisted of six compartments, while the linear pouch had only four. The discrepancies among these values should be considered for future research to investigate making the pouches more efficient. Their efficiency can be accounted for through the development of these models, as well as by developers who may build upon these findings.

Additionally, as can be seen from the graphs, the pouch motors experience a maximum force they can exert, a maximum bending angle, displacement, and volume. This occurs because the input pressure of the device can only go to a certain value before popping the seals of the plastic. Therefore, the pouches are limited by their physical composition. This observation may inspire future investigations to investigate additional low-cost sealable materials.

Initially, based on the review of the literature, it was hypothesized that the relationships between pressure and force and pressure and bending angles would be nonlinear, due to the results surrounding other forms of pneumatic actuators. However, the data presented in this paper rejects the initial hypothesis, as these relationships were linear.

The conclusions presented are limited to the accuracy of the equipment used and the trials conducted. While measures were taken to min- imize error as much as possible, the Vernier sensors do not always provide accurate readings. Finally, this paper only considers two different patterns of pneumatic pouch motors when there are more possibilities.

Implications

Through the development of these mathematical models, other researchers will be able to build on top of this and begin to develop pouch motors for specific uses. For example, pouch motors provide the functionality ideal to use for medical purposes because of their soft and flexible nature. In addition, they also provide potential uses in education to introduce students to different forms of robotics without the large costs. As pneumatic pouch motors offer a lower cost and easier to make alternatives, education systems may be more inclined to use them.

These uses provide real world applications, making the implications of this research that much more prominent. With their most promising uses being rehabilitation, these forms of pneumatic actuators will help to enhance patient care by providing the potential for a home-based device. This from of robotics provides easy-use for patients because of their portable and adaptable nature, along with being a cost-efficient option that provides the same health benefits as physiotherapy. This form of treatments will help to lower treatment costs and the strain on physiotherapists, as they will not need to see as many patients as often. These findings will contribute to the future use of medical technologies for patients care, as they will help to combat the increasing number of health concerns related to the extended life expectancy of the population, while also providing the potential for education.

Future Directions

Future research within this field would look to include the incorporation of other varieties of pneumatic pouch to compare their experimental results. By studying a wider variety of pouch motors, it could be determined which of them is most able to replicate bodily movements and functions, such as grasping, to be developed for patient use. Investigating the effects of pouch length, width, and the number of individual compartments as well as exploring efficiency improvements also provides the potential for future research as these investigations will open up more opportunities for the use of pneumatic pouch motors.

REFERENCES

Al-Fahaam, H., Davis, S., & Nefti-Meziani, S. (2018). The design and mathematical modelling of novel extensor bending pneumatic artificial muscles (EBPAMs) for soft exoskeletons. Opens in new Window Publication: Robotics and Autonomous Systems, 63-74.

Andrikopoulos, G., Nikolakopoulos, G., & Manesis, S. (2015). Design and development of an exoskeletal wrist prototype via pneumatic artificial muscles. Meccanica, 2709-2730.

Ates, S., Haarman, C. J., & Stienen, A. H. (2017). SCRIPT passive orthosis: design of interactive hand and wrist exoskeleton for rehabilitation at home after stroke. Autonomous robots, 41(3), 711-723.

Bhuiyan, M., Choudhury, I. A., & Dahari, M. (2015). Development of a control system for artificially rehabilitated limbs: a review. Biological cybernetics, 141-162.

Bianchi, M., Fanelli, F., Meli, E., Ridolfi, A., Vannetti, F., Bianchini, M., & Allotta, B. (2018). Optimization-based scaling procedure for the design of fully portable hand exoskeletons. Meccanica, 53(11-12), 3157-3175.

Biggar, S., & Yao, W. (2016, October). Design and Evaluation of a Soft and Wearable Robotic Glove for Hand Rehabilitation. IEEE Transactions on Neural Systems and Rehabilitation Engineering, 24(10), 1071- 1080.

Bishop-Moser, J., & Kota, S. (2015, June). Design and Modeling of Generalized Fiber-Reinforced Pneumatic Soft Actuators. IEEE Transactions On Robotics, 31(3), 536-545.

Boyraz, P., Runge, G., & Raatz, A. (2018). An Overview of Novel Actuators for Soft Robotics. Actuators, 1-21.

Chu, C.-Y., & Patterson, R. M. (2018). Soft robotic devices for hand rehabilitation and assistance: a narrative review. Journal of NeuroEngineer- ing and Rehabilitation, 1-14.

Conti, R., Meli, E., Ridolfi, A., Bianchi, M., Governi, L., Volpe, Y., & Allotta, B. (2017). Kinematic synthesis and testing of a new portable hand exoskeleton. Meccanica, 2873-2897.

Davis, S. (2018). Pneumatic Actuators. Actuators, 1-3.

Greer, J. D., Morimoto, T. K., Okamura, A. M., & Hawkes, E. W. (2017). Series Pneumatic Artificial Muscles (sPAMs) and Application to a Soft Continuum Robot. IEEE International Conference on Robotics and Automation, 5503-5510.

Maeder-York, P., Clites, T., Boggs, E., Neff, R., Polygerinos, P., Holland, D., . . . Wee, C. (2014). Biologically inspired soft robot for thumb rehabilitation. Journal of Medical Devices, 8, 1-3.

Niiyama, R., Rus, D., & Kim, S. (2014). Pouch Motors: Printable/Inflatable Soft Actuators for Robotics. IEEE International Conference on Ro- botics & Automation (ICRA), 6332-6337.

Niiyama, R., Sun, X., Sung, C., An, B., Rus, D., & Kim, S. (2015). Pouch Motors: Printable Soft Actuators Integrated with Computational Design. Soft Robotics, 2(2), 59-70.

Rocha, R. P., Lopes, P. A., de Almeida, A. T., Tavakoli, M., & Majidi, C. (2018). Fabrication and characterization of bending and pressure sen- sors for a soft prosthetic hand. Journal of Micromechanics and Microengineering, 28(3), 1-10.

Sebastian, F., Fu, Q., Santello, M., & Polygerinos, P. (2017). Soft Robotic Haptic Interface with Variable Stiffness for Rehabilitation of Neuro- logically Impaired Hand Function. Frontiers in Robotics and AI, 1-9.

Shrivastava, A. (n.d.). Programmable Air. Retrieved from https://hackaday. io/project/129278-programmable-air

Villegas, D., Vanderborght, B., Van Damme, M., Beyl, P., & Lefeber, D. (2011). Third–Generation Pleated Pneumatic Artificial Muscles for Robotic. Advanced Robotics, 1-23.

Appendix A

Figure A1: Programmable Air with connection to computer with Arduino software and connection to pneumatic pouch motor.

APPENDIX b

Figure B1: Template of Curling Pouch Motor

APPENDIX C

Figure C1: Templace of Curling Pouch Motor

APPENDIX D

Table D1: Explanation of variables used throughout the results section

APPENDIX E

Figure E1: Length of curvature and bending angle

APPENDIX F

Figure F1: Force-Displacement Model for Linear Pouch

APPENDIX G

Figure G1: Force-Displacement Model for Curling Pouch

APPENDIX H

Figure H1: Work Calculations

Figure H1 (continued)

ABOUT THE AUTHOR

Hannah Boucher

Hannah is studying Medicinal Chemistry at the University of New Brunswick continuing her passion for learning. While her primary interests lie in chemistry, she is also fascinated by mathematics and genetics. She hopes to pursue a career within the medical field to provide help and support for those in need, with a particular interest in neuroscience and geriatrics. Outside of school, Hannah enjoys volunteering on the transitional care unit of the Hospital, playing basketball, and hanging out with friends and family.